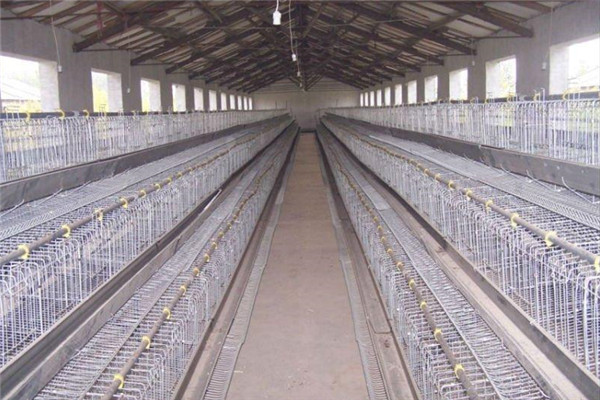

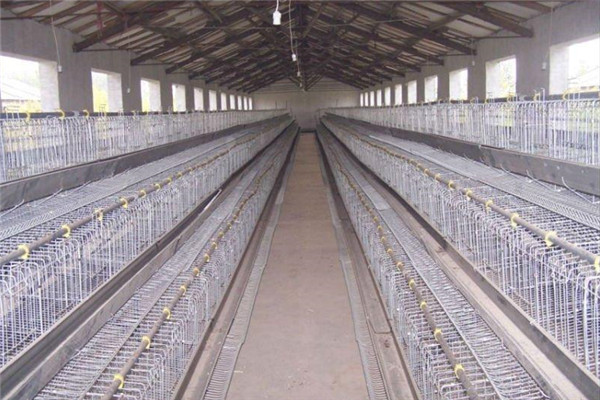

With the promotion of the mechanization of the chicken industry in the country, the stepped and stacked egg cages have been improved and promoted for ghana layer poultry farm for 5000hens , the mechanization level has been greatly improved and improved, and other types of cages have gradually been eliminated by the market. In the current industry, the semi-stepped type is also referred to as a stepped or A-type cage, and the stacked type is also referred to as an overlapped or H-shaped cage. The semi-stepped cage has certain advantages in ventilation and lighting. The equipment can realize the combination of mechanical automation and manual operation, so it can also cope with emergencies such as power outages. The stacked cages have significant density in breeding. The superiority, with the improvement of rural power facilities and the development of automation equipment, has also been widely used.

The current common stepped egg cage form:

1) The angle between the bracket bracing and the ground is reduced to 650-750 for ghana layer poultry farm for 5000hens . The central area of the cage system is larger, which is conducive to the vertical and vertical flow of air, so the ventilation effect is better; the lower cage is displaced more vertically in the vertical direction, so that the chickens in the lower two layers of cages are more fully in contact with the aisles. The light source is good, so the lighting effect is good.

2) Remove the dung board from the top of the middle and lower chicken cage for ghana layer poultry farm for 5000hens . The overlap of the upper and lower cages in the vertical direction is only 1/3 of the depth of the cage, and the cage is close to 1/3 of the front net as the feeding area of the chicken. The possibility that the chickens will drop the feces to the lower layer in this area Smaller, a small amount of feces will fall off the egg shield plate in front of the cage, so there is no need to install a manure board.

3) The cage is consistent for ghana layer poultry farm for 5000hens . Since the lower layer is free of the installation of the dung board, the top net of the middle and lower layer chicken cages can be designed to be horizontal, so that the chicken cages in each layer are completely identical, which brings cheapness to the standardized production of the cage net and the assembly of the cage system.