Baby chicken cage we introduced here is mainly rearing baby egg laying chicken, Chick cage also is named to pullet cage or brooder cage. if you want to learn how to breed baby chicken in the cage ,please check detailed information below .

Best chick cage rears baby egg laying chicken from one day old chicks, after around 2 months ,it can produce layer , farmers will transport them to egg laying chicken cage also named layer cage, finish the whole rearing processing.

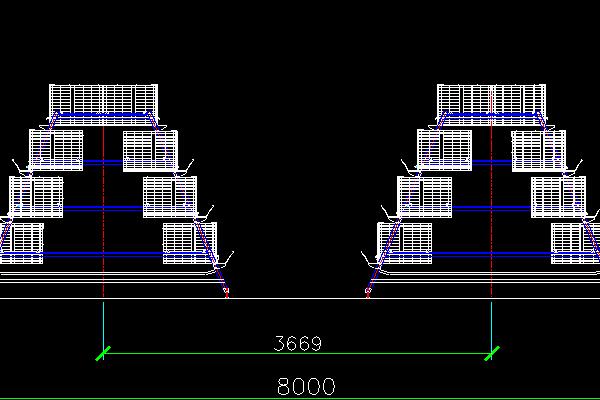

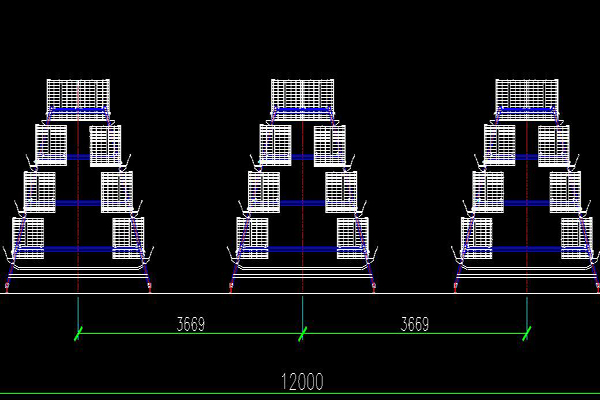

1,you know , temperature is very important for baby chicks .so most poultry farm house is closed in order to make sure the baby is not cold .our customer from Mozambique found us by our previous customer in his country .we designed the project based on his information ,hence we design one of two house is 66m length *12m width *3.8m height ,the another house is 66m length *12m width *3.8m,please check our drawing .

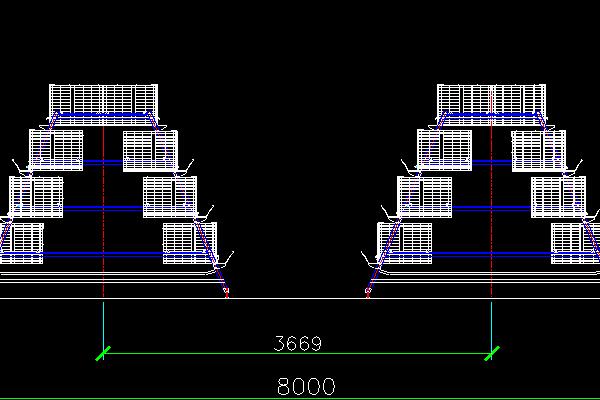

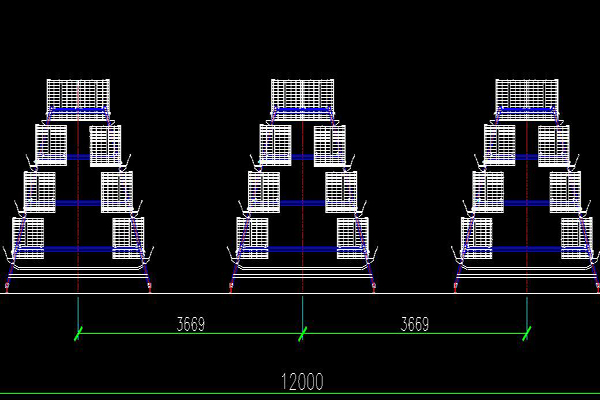

2,the layout of baby chicken cage in one house is A type 4tier full automatic baby chicken cage ,one unit size is 1.95m*2.4m*2.1m,one cell can hold 20birds ,it is 2row .In another is 3row ,please check our drawing .

3,the below is our baby chick cage and automatic drinking system , the cage resist corrosion ,it can last 10-15years, the nipple drinker is not leak any water, it is easy for baby chicken .

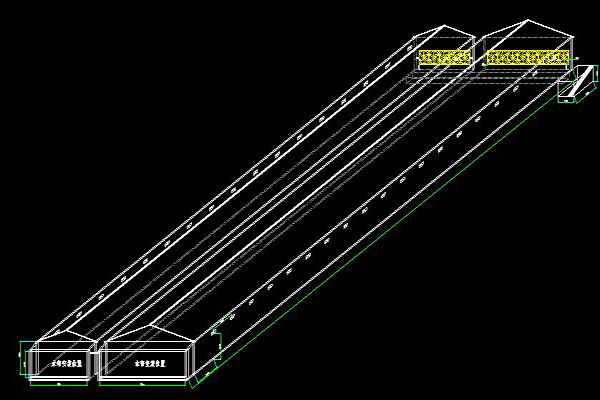

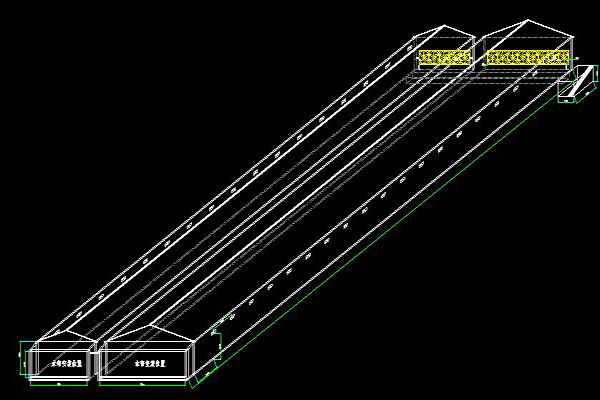

4, Automatic Feeding System: The automatic feeder consists of a frame, a walking power output system, a walking system, a material discharging power system, a material quantity adjusting system, and a power distribution system. The automatic feeder traveling power system is driven by a vertical motor equipped with an advanced cycloid reducer, which realizes no loss in driving, low failure rate, long service life, stable operation, low noise, and reduced noise impact on chickens. Egg production rate. The lifting system consists of a flat conveyor and a vertical conveyor. The vertical conveyor conveys the feed from the ground to the flat conveyor. The flat conveyor evenly distributes the feed to each hopper on the feeder. The hoppers of the feeders are all When full, the photoelectric switch receives the signal to disconnect the control circuit of the motor and finish the work of conveying the feed. It reduces the work intensity, reduces the waste of man-hours, and fully improves the work efficiency.

5, Automatic Manure Removal System: The conveyor belt excrement manure belt is installed under each layer of chicken cage. When the machine starts, the motor reducer passes the automatic rollers of each layer of the chain's shareholders to generate friction force under the force of the forced roller and the automatic roller. The shareholder's manure belt is moved along the length of the cage group, the chicken manure is transported to one end, and the manure scraper plate provided at the end is scraped off, and then the cleaning work is completed. Drive power 1.5KW, fecal tape 8-1.2 thick, conveyor belt width can be customized, the use of the length of 100 meters. Conveyor belt cleaning machine to dry the chicken manure into pellets. The chicken manure reuse rate is high. The chicken manure can be directly sent to the feces car outside the poultry house. Chicken manure is not fermented in the house, and the air in the house is fresh. Chicken health can effectively prevent infectious diseases

6,the exhaust fan can bring fresh air and cooling wind ,when the baby growing gradually, it can low temperature.

7,lighting is very key for baby chicks ,it need much lights than layer .